STAINLESS STEEL CABLE SYSTEM

Generally stainless-steel cables are selected in applications where the cable system is highly visible or as an architectural feature for example transparent facades, glass curtain wall facades, exhibitions and convention centre halls, pavilions, footbridges and cable net roofs. Stainless steel cables are available as Full Locked Coil (type FLX) or Open Spiral Strand (type OSX).

-

Stainless Steel Fix Swaged Sockets

The two stainless steel fix swaged sockets are open swaged sockets (XMAC) and closed swaged sockets (XMCC). -

Stainless Steel Adjustable Swaged Sockets

The three stainless steel adjustable swaged sockets are cylindrical swaged socket (XFLT), adjustable open swaged socket with turnbuckle (XTBC) and adj... -

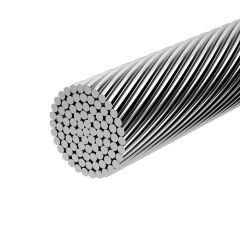

STAINLESS STEEL OPEN SPIRAL STRAND (OSX)

OSX cables are manufactured using layers of helically wound stainless steel round wires around a central core. The standard stainless-steel grade used... -

STAINLESS STEEL FULL LOCKED COIL ROPES (FLX)

FLX ropes are manufactured using outer layers interlocking Z-shaped stainless-steel wires around a core of stainless-steel round wires. The standard s...

Stainless steel cable systems can be supplied up to 42mm diameter. With swaged sockets and larger diameters with stainless steel sockets. Generally stainless steel cables are selected in applications where the cable system is highly visible or as an architectural feature for example transparent facades, glass curtain wall facades, exhibitions and convention centre halls, pavilions, footbridges and cable net roofs. Stainless steel cables can be supplied with a polished finish. Stainless steel cables are available as Full Locked Coil (type FLX) or Open Spiral Strand (type OSX). The standard stainless steel grade used to produce OSX and FLX is 1.4401 (AISI 316). Each wire has a minimum tensile strength of 1470 N/mm2.

Stainless steel cables do not need for an internal corrosion inhibitor compound. Therefore, they are usually produced dry or with a light manufacturing oil. Each individual stainless steel is tested and verified for physical properties including tensile strength, bending and ductility in accordance with EN 10264-4.

Customized stainless steel casted sockets are also available to suit customer project specific requirements and specifications.