HDPE Cable System

High Density Polyethylene (HDPE) can be applied to structural cables for improving corrosion protection, increasing visibility and for architectural, aesthetic reasons. This option has an impact on the sockets choice which are specifically designed and manufactured to accommodate the additional HDPE layer within the socket neck. Teufelberger-Redaelli’s HDPE sheathed cables are designed and produced to extend and prolong the cable systems lifespan, offering a good resistance to oils, water, chemicals and abrasions.

-

HDPE Fix Sockets

Our four HDPE fix sockets are fix fork socket (TTFH), fix cylindrical socket (CYFH), adjustable cylindrical socket with shims (CYSH) and cylindrical s... -

HDPE Adjustable Sockets

There are several types of HDPE adjustable sockets. Adjustable fork socket (TBFH), bridge socket (BRCH) and all different types of cylindrical sockets... -

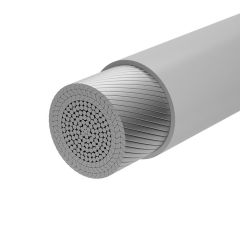

FULL LOCKED COIL ROPE WITH HDPE (FLCH)

The High Density Polyethylene sheathing provides an additional protection system to the cable. Thanks to the available full range of color, the HDPE l... -

OPEN SPIRAL STRAND WITH HDPE (OSSH)

The High Density Polyethylene sheathing provides an additional protection system to the cable. Thanks to the available full range of color, the HDPE l...

In many structures in order to increase the duration of service life, the galvanized cables are sheathed with a continuous and wear-resistant HDPE sheathing, providing additional protection system. The HDPE sheathing sometimes is applied for increasing visibility or for aesthetic reasons. The adapted sockets for the cable with High Density Polyethylene (HDPE) sheathing are designed and manufactured to accommodate the additional HDPE layer within the socket neck.

High Density Polyethylene (HDPE) Coated Cables

For increasing long-term durability or high visibility OSS and FLC cables can be additionally protected with a vacuum extruded HDPE covering. The HDPE is applied by a continuous extrusion process and is closely monitored under factory-controlled conditions. This external plastic coating provides an additional corrosion protection stage on outer surface of the cables, assuring optimum durability for cables even in very aggressive environments.

This option also allows clients to benefit from more aesthetic choices in their cable selection with a large spectrum of RAL colours available extruded, co-extruded over a carbon black foundation HDPE layer, or a double coloured layer. Additionally, it is also possible to extrude an axial line mark along the length of the cable.

HDPE relevant properties:

- Very low maintenance needed during the cable lifetime.

- UV stability against solar radiation.

- Weathering resistance.

- Full spectrum of outer layer final RAL colours.

- Typical HDPE wall thickness is 10% of the internal strand diameter.

- Cables are capable of being coiled on a diameter of 30 times cable diameter.

Each individual wire is tested and verified for tensile strength, ductility, elongation at fracture, bending, torsional properties and adhesion of zinc coating in accordance with EN 10264 and EN 12385-10. The external plastic HDPE coating is applied by continues extrusion process and is closely monitored under factory-controlled conditions. HDPE thickness is based on nominal diameter of OSS cables.

Main properties: High axial stiffness, high strength to weight ratio, high fatigue resistance, torque balanced, less required maintenance during the lifetime, UV stability against solar radiation, weathering resistance.