Coatings and special treatments

By using different impregnation and coating techniques TEUFLEBERGER is able to enhance the specific characteristics of their safety and rescue ropes.

Technique

S.Y.I.S. – Single Yarn Impregnation System

Before braiding the rope, all single yarns are being dipped and fixed. Added color pigments allow to apply any desired color.

Rope Coating

After braiding the rope, the complete construction is dipped in a calibrated procedure. Again, a final fixing step will be carried out to ensure that applied substances remain attached to the rope’s fibers as long as possible.

Coating materials

We use a huge variety of compositions to influence specific rope properties in a carefully controlled manner. For this purpose, we rely on the following substances:

- Polyurethane

- Silicones

- Wax

- Acrylates

- PTFE

Rope properties

These are some of the properties that we are able to improve with coatings and special treatments:

- High yarn on yarn abrasion resistance

- High yarn on metal abrasion resistance

- UV-resistance

- Water repellence

- Mold resistance

- Keeping color

- Traction

- Fire retardance

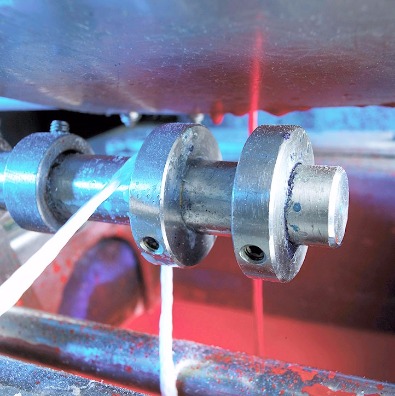

- Improved CBOS fatigue (cyclic bend-over-sheaves)