High performance steel wire ropes for the offshore industry

Solutions for the Oil & Gas and renewable energy industry

TEUFELBERGER-REDAELLI develops and produces innovative high quality steel wire rope solutions for the high demands of the offshore sector. Our extensive expertise and experience are a guarantee of absolute safety, especially in difficult and challenging environments.

Decades of cooperation with system and crane manufacturers have strived, and continue to strive, superior results in our steel wire ropes design. State of the art developments as well as joint efforts with both customers and wire material suppliers have allowed us to consistently produce high performance steel wire ropes: high load capacity, lifetime, wear resistance, perfect fit to successfully withstand the severe requirements of the Oil & Gas and energy industry. Deepwater, salt water, wind, sand, etc. are environmental factors TEUFELBERGER-REDAELLI steel wire ropes are designed to thrive in.

Teufelberger-Redaelli 's rope portfolio includes a large number of special ropes for the Oil & Gas and Offshore sector: Special lifting systems for cable-laying units, over 5,000t cranes, deployment systems, winches, extreme subsea applications: these are some of the deepwater challenges that Teufelberger-Redaelli ropes faced and won with flying colours. Up to the Guinness World Record!

- Ropes for deepwater/subsea operations

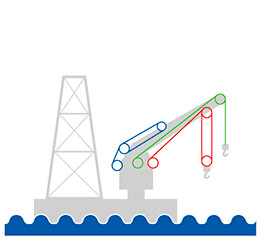

- Ropes for offshore cranes on drilling platforms and wind turbine installation vessels•

- Ropes used on vessels such as

- Ropes for knuckle boom cranes

- Ropes for deep sea winches

- Ropes for active heave compensation systems (MRT – marine riser tensioners)

- Ropes for drilling applications (drilling systems).

Minimal downtimes are a milestone on the way to optimum cost-effectiveness.

Replacement ropes can only be stored in limited numbers. Therefore, any unforeseen rope change requires a major logistical effort. Especially on offshore platforms, any unscheduled downtime of a crane generates considerably high extra costs. These costs are unnecessary and can be avoided with a Teufelberger-Redaelli high-performance steel wire rope. In addition, crane ropes from Teufelberger-Redaelli markedly reduce overall lifetime costs. Because we know what matters: flexibility, quality, perfect spooling characteristics, reliability, safety, and longevity.Nevertheless, if a problem does occur, Teufelberger-Redaelli 's rope professionals will give you excellent support. Whatever problem occurs, you can reach our network of support technicians around the clock our 24 hour hotline. We make sure to keep your downtimes to a minimum.

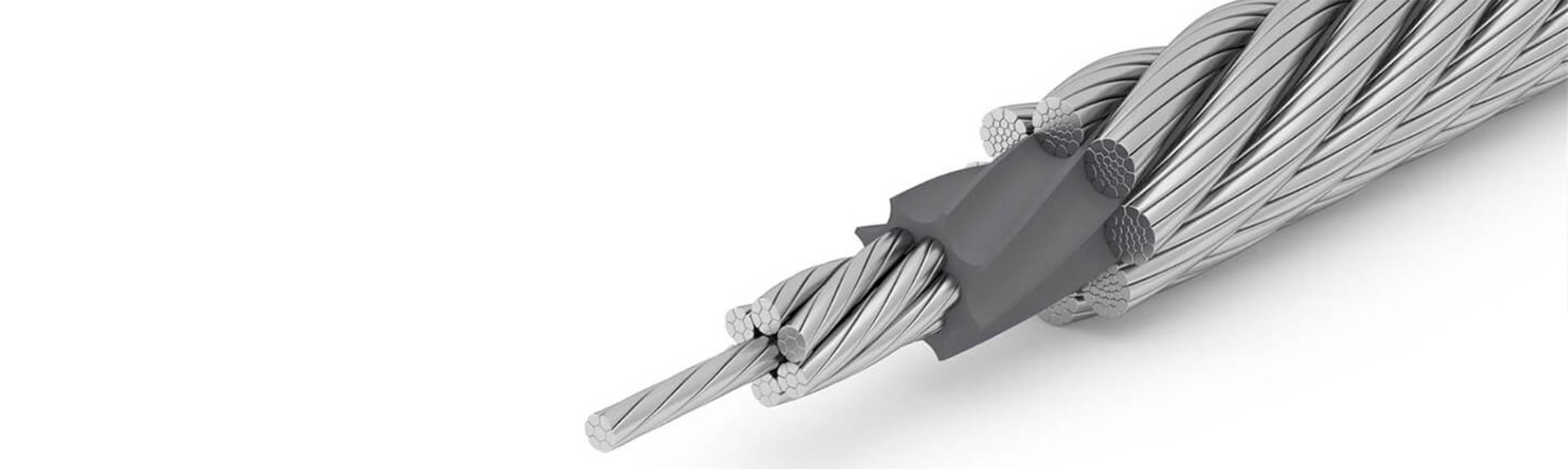

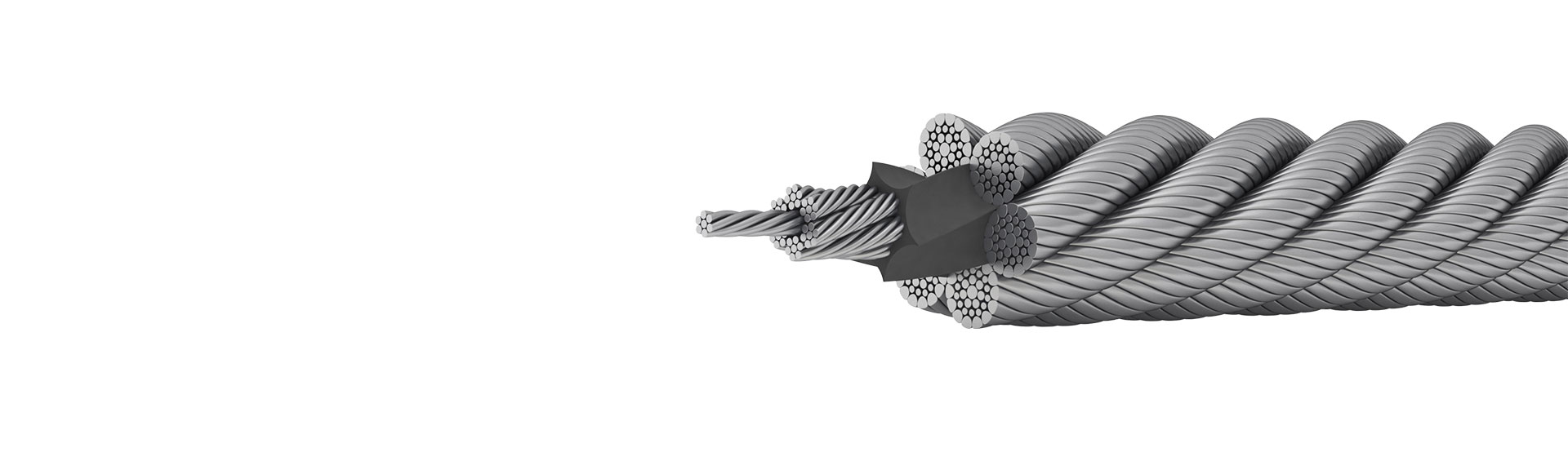

The rope design makes the difference

The construction of a high-performance steel wire rope requires detailed technological and manufacturing know-how. The PLASTFILL® technology developed by Teufelberger-Redaelli is a lubricated steel core encased in a compact plastic coating. The SUPERFILL® compaction technology is a special process used to compact the individual wire strands of a steel wire rope. Galvanized wires and special lubrication afford additional protection against corrosion. This is of particular importance in the oil and gas industry.High performance steel wire ropes used as hoist ropes, auxiliary hoist ropes, and boom hoist ropes Teufelberger-Redaelli offers a vast variety of rotation-resistant and non-rotation-resistant high-performance steel wire ropes for the oil & gas segment that are equally effective as hoist ropes, auxiliary hoist ropes, or boom hoist ropes. Their scope of usage ranges from ropes for cranes, winches and marine riser tensioner systems to drilling ropes for draw works.