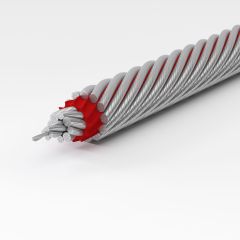

Blair drum winder hoist rope

Hoist ropes in underground mining are the lifeline of each deep hoisting shaft. Therefore, safety and reliability are absolute prerequisites.

-

7MINE®

The proven 7-strand rope designed to replace conventional triangular strand ropes without changing existing hoisting performance parameters (custom fi... -

7MINE® HD

The proven 7-strand design is extremely resistant to negative external influences. -

8MINE

An 8-strand rope designed to replace conventional triangular strand ropes without changing existing hoisting performance parameters (custom fit). -

12MINE 440(P)

12-strand rotation resistant rope with optional PLASTFILL® insert between the steel core and the outer strands. -

12MINE 460(P)

12-strand rotation resistant rope with optional PLASTFILL® insert between the steel core and the outer strands. -

FLEXMINE® 440(P)

15-strand rotation resistant rope with optional PLASTFILL® insert between the steel core and the outer strands. -

FLEXMINE® 460(P)

15-strand rotation resistant rope with optional PLASTFILL® insert between the steel core and the outer strands. -

Flexpack® Mining(P)

Best-in-class 35x7 rotation resistant rope for use in a vast variety of heavy duty underground mining applications in challenging environments.

With hoisting rates and payloads steadily rising and the wish for ever-growing longevity, the requirements put on the quality of steel wire ropes have become extraordinarily high. Here’s Teufelberger-Redaellis’s answer to these challenges:

- Exclusive use of high grade materials

- Use of state-of-the-art production technologies

- Close cooperation with our customers

- Intensive work performed by our Research & Development department

- Continuous quality control (ISO 9001), as well as

- Close cooperation with manufacturers of hoisting installations

Teufelberger-Redaelli offers a wide range of hoist ropes for blair drum winder hoists. The most important aspect beside safety is economic efficiency and hence the right choice of rope for the given conditions. What has to be considered, in addition to the required minimum breaking force and the specific weight of the rope, is the blair drum winder specific mechanism causing damage to the rope. Such mechanisms are associated with the following types of damage:

- Wire breakage due to wear and plastic deformation in the cross-over zones

- Wire breakage due to bending fatigue

- Corrosion caused by external influences such as humidity, salts, and other corrosive substances

The decision as to which hoist rope from Teufelberger-Redaelli is the best choice for your application and your specific conditions should always be made in consultation with our specialists. Moreover, in many cases it’s a good idea to have the hoisting system surveyed so that the hoist rope can be exactly adapted to the hoisting drum. Such surveying work is performed by our own application engineers on site.

Of course, Teufelberger-Redaelli hoist ropes can be delivered with various wire coatings, depending on what you need.