Fiber ropes for drum winches

You need a rope for a drum winch? We have the tailor-made solution for you.

Our covered fiber ropes of high strength HMPE material feature enormous breaking forces. Both in single and in multilayer spooling, our synthetic ropes afford excellent radial stability for the hauling and hoisting of loads. Depending on what our customers need, we manufacture these synthetic ropes with various cover constructions such as HMPE, PES, or a combination of HMPE/PES. Our special service includes the CE certification of the ropes as needed.

-

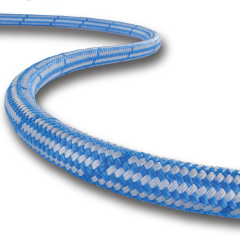

HyperTEN+

HyperTEN+ is a thermally pre-stretched high-end fiber rope made of original Dyneema® SK78 fibers. It is mainly used in industrial applications that re... -

DuraTEN+

The high-performance fiber rope DuraTEN+ offers highest breaking forces, bending cycle resistance and abrasion resistance. This fiber rope serves as a... -

rackLITE

rackLITE was developed especially for safe load lifting without lubrication and maintenance in intralogistics. rackLITE offers innovative rope techno... -

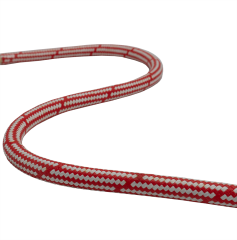

DuraTEN

The DuraTEN fiber rope excels with high breaking forces at minimal weight, high bending fatigue strength as well as abrasion resistance, and a long se... -

HyperTEN

HyperTEN is our thermally pre-stretched high end fiber rope for highest technical requirements and is ideally suited as a replacement for steel wire r... -

Globe 5000 MK2

The technical fiber rope Globe 5000 MK2 excels with high friction values and breaking forces, very low stretch, as well as minimal core/cover displace... -

Sirius 300 XG

Sirius 300 XG excels with an excellent price/performance ratio at very good friction values, good breaking forces and low stretch.

Our ropes - your benefit:

- Our ropes weigh 7 times less than steel wire ropes.

- The synthetic ropes excel due to highest breaking force and perfect spooling behavior.

- Fiber ropes are not subject to corrosion or soiling caused by rope grease.

- Our synthetic ropes are no source of injury.

- The ropes are characterized by quick and easy handling, thus allowing the user to work ergonomically.

- We offer you a flexible design of the ropes.

- We manufacture a unique rope end termination with socketing cone without any loss of breaking force.

- You can do the socketing yourself, for example if a rope has to be shortened.

- The ropes are extremely abrasion resistant while featuring minimal stretch and very high radial stability.

- Our ropes feature a very high reverse bending fatigue strength - resulting in a long service life.

- Fiber ropes do not cause wear on sheave surfaces.

We offer the following rope end terminations:

- Socketing: unique rope end termination with socketing cone without any loss of breaking force

- Spliced eye

- Stainless steel or tubular thimble

- Various types of hooks

- Installation aids and protection sleeves