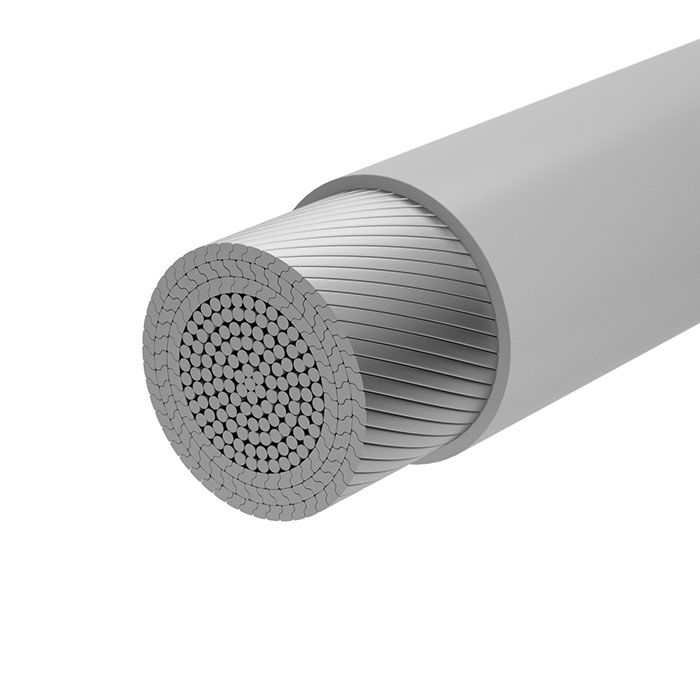

FULL LOCKED COIL ROPE (FLC)

Teufelberger-Redaelli Full Locked Coil (FLC) ropes are manufactured using a combination of helically wound, hot-dip galvanised, high strength steel round wires and interlocking Z-shaped wires.

In FLC cables outer layers of interlocking Z shaped wires are helically spun around an OSS core, avoiding the external agents get into the inner side of the cable. The combination of the closed design construction of a FLC cable, with Galfan (95% Zn / 5% Al) coated outer Z shaped wires and an internal zinc rich paste blocking compound that Teufelberger-Redaelli cables use result in a finished cable that has several stages of corrosion resistance.

The outer layers of Z-shaped wires are generally spun in opposite directions around a central core of round wires. Each individual wire is tested and verified for tensile strength, ductility, elongation at fracture, bending, torsional properties and adhesion of zinc coating in accordance with EN 10264 and EN 12385-10. Main properties: excellent axial stiffness, optimum strength to weight ratio, excellent fatigue resistance, torque balanced, excellent resistance to lateral forces meaning most suitable for cable clamping.

Specifications:

- Excellent axial stiffness

- Optimum strength to weight ratio

- Excellent fatigue resistance

- Torque balanced

- Suitable for cable clamping.

- Four-stages Corrosion protection system.

- Teufelberger-Redaelli patented anti-vibration solution (Surface Treatment)

- Cable Stayed bridges

- Hangers of Arch bridges

- Hangers and main cable of suspension bridges

- Guy ropes, Cable net roofs

- canopies

| Nominal Tensile Strength | Proof Stress Rp 0.2 | Elongation at break | Modulus of Elasticity |

|---|---|---|---|

| 1570 Mpa (after hot dip galvanizing) | 1180 Mpa | 4% min on 250mm (EN12385-10) | 160 ± 10kN/mm² |