...my rope gets in contact with salt or tree sap?

One of the main questions in the rope world is “Is my rope still good to work with?” Manufacturers specify a theoretical service life in their instructions for use. This is mainly based on very rare use. The actual service life, especially when the rope is heavily used, depends on a lot of factors that are beyond the control of manufacturers. In this series, TEUFELBERGER presents the results of a study made on “Deliberate damage of ropes”. In this article, we answer some frequent questions on the impact that salt and tree sap has on the strength of the ropes.

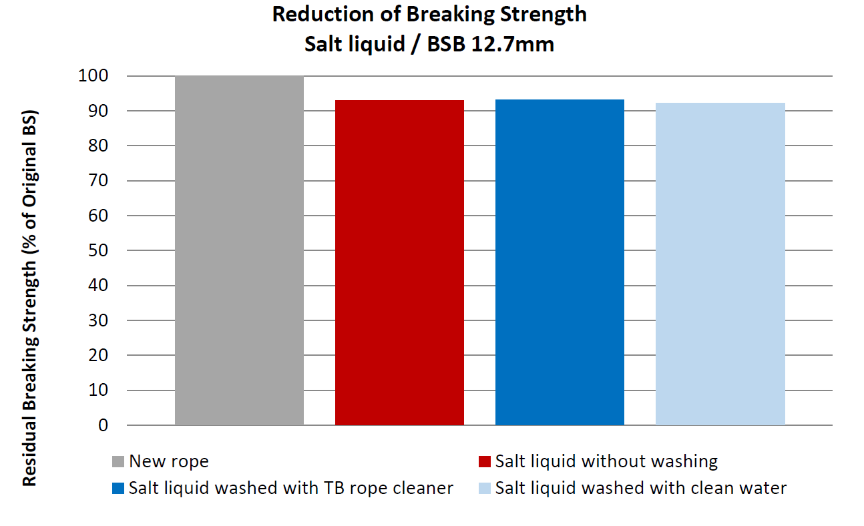

1. Salt liquid

Especially in offshore applications, ropes can get in contact with salt water. Therefore the influence of a saturated NaCl solution in water (36g NaCl/100g H2O) similar to the Mediterranean Sea was tested on the ropes. The ropes were submerged one time into the liquid, then pulled over pulleys for 10 times to simulate application and left to dry naturally. One part of the treated samples were then washed with clean water, another part with TEUFELBERGER rope detergents, before they were tested for their residual strength.

The following rope was tested

- Braided Safety Blue (BSB) 12.7 mm (Polyamide core / Polyester cover)

The tests show slight reduction of breaking strength (approx. 7-8%) in all tested treatment versions. It can be assumed that the damage increases if the ropes are repeatedly exposed to salt water. Washing, neither with clean water, nor with TEUFELBERGER rope detergent, does not change this fact. Material characteristics suggest that Polyester is more resistant than Polyamide, and it does not take in water that easily. Therefore it is recommended to use Polyester ropes or at least ropes with a polyester cover in applications with salt water.

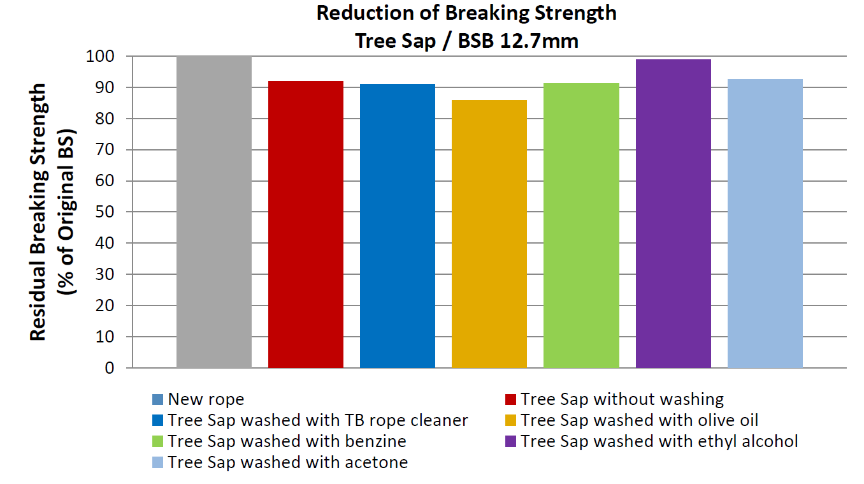

2. Tree Sap

In Tree Care, users are regularly confronted with contamination of their ropes from tree sap. We included the influence of tree sap to our tests including some possible cleaning options to our test series.

For these tests, tree sap was applied to the rope samples one time and then it was tested for its residual breaking strength. In addition, different ways of cleaning were tested in this test series. One sample each was treated with the following options and then tested for its residual breaking strength:

- Washing 30°C with Teufelberger Rope detergent

- Washing with Olive Oil Extra Vergine

- Washing with benzine

- Washing with ethyl alcohol

- Washing with Acetone

The following rope was tested:

- Braided Safety Blue 12.7mm (Polyamide core / Polyester cover)

The results show that resin and the cleaning afterwards damage the rope to a certain degree. If the properties of the rope are limited by the resin (stiff, sticky, etc. …) the resin should be removed or if that is not possible, the rope should be retired. For cleaning ethyl alcohol or acetone showed the best results. Soak the affected area in the solution for 10 minutes, then rinse it in clean water and let it dry naturally. This is not suitable for large-scale applications.

Conclusion & Recommendations

- Salt or tree sap damage the rope to a certain extent.

- Damages are not always visible from the outside, please keep that in mind!

- Washing can’t repair or fix the rope once dirt entered into the core.

- Avoid dirt, salt or tree sap as much as possible.

- If the rope shows visible damage or the properties of the ropes are impacted by dirt, retire the rope immediately!