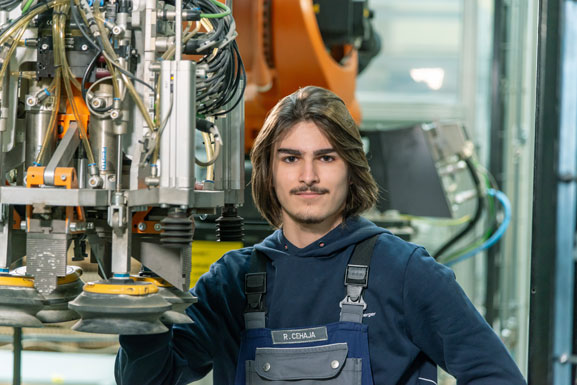

Process Technician (Wels und St.Aegyd)

Apprenticeship to become a Process Technician

Become an allrounder on the production floor! You will plan tools and devices of production machines and systems, read work instructions and schedules, monitor systems and production processes, and frequently perform machine maintenance jobs.

Facts

Duration: 3.5 years

Location: Vogelweiderstraße and Böhmerwaldstraße, Wels and St. Aegyd/Lower Austria

Vocational school: Attnang

Working hours: 7.00 a.m. - 4.00 p.m., every 2nd Friday until 12.00 p.m. (noon)

Apply now if ...

- you have completed your compulsory education by autumn

- you like to grasp the big picture and join the dots, and are a natural when it comes to engineering

- you are good at logic and mathematics

- you enjoy learning new things and are able to quickly apply new insights in practice

- you are punctual, reliable, and enjoy working on a team

What you learn at Teufelberger as an apprentice process technician

You will be trained for many activities on the production floor and for working on production machines. You will also get to know the quality assurance department and the metalworking shop, you will handle daily maintenance jobs such as changing filters, draining condensate, and emptying dust containers. In production planning, you will ready tools for our machines.

From the second year of your apprenticeship onward, you will be given the opportunity to come along to trade shows and independently conduct tours around the factory. Your work offers plenty of variety, no two days are the same. Depending on your interests and abilities, you will have the chance to work independently and be assigned special projects. Later on, you can also specialize in a certain area, depending on your skills and interests.

Your specific tasks include:

- Learning the entire production process, step by step: from the use of tools to the production systems and through to quality assurance

- Close cooperation with all departments involved in production processes: Maintenance, Production, Quality Assurance, Research & Development, Logistics

- Processing of plastics and steel wire ropes, and operating the respective systems

- Assembly, maintenance, and refitting of machine and system components

- Acquiring knowledge in electrical engineering and electronics

- Quality assurance and documentation

Process technician at Teufelberger – more than an apprenticeship

Time and again, Teufelberger apprentices are also assigned special projects such as charity campaigns or climate projects. Upskilling days on which you will travel to other places with your fellow apprentices also add variety.

Frequently asked questions

Not at the very beginning. First, you need to familiarize yourself with the processes and master them. However, once you have completed your basic training, which takes about 2 to 3 weeks, you will already be helping your colleagues in your shift. On average, about 12 colleagues will be working in your shift. As a process technician, you will be working together with other apprentices – also within the scope of interdepartmental projects. There is one main trainer, and in day-to-day operations, your trainers will be the team leaders and the machine setters. Depending on your skills, you will be working independently a lot, and your colleagues will help you with both advice and hands-on assistance. You will attend a vocational school in Attnang for a 10-week block. From 7.00 a.m. to 3.45 p.m., including a half-hour break. Every second Friday, your work day will end at 12 p.m. (noon).Will I be involved in everyday operations right from the start?

How large is the team?

Will some of my colleagues be apprentices?

Who are my trainers?

Which vocational school will I be attending?

What will my working hours be like?

Do you have any further questions?